Milling Cutters

Red denotes Somta Premium Products

Product

Code

Type

Spec.

Range

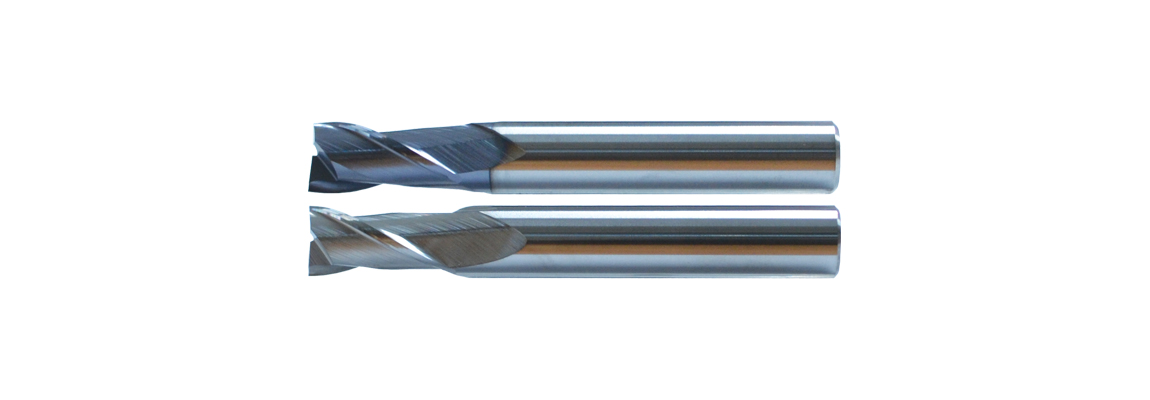

Solid Carbide 2 Flute End Mills – Regular Length – Plain Shank – Uncoated for Aluminium

Milling keyways and slots to size in one cut. Designed for plunging operations.

02A

WORKS STD.

1-16

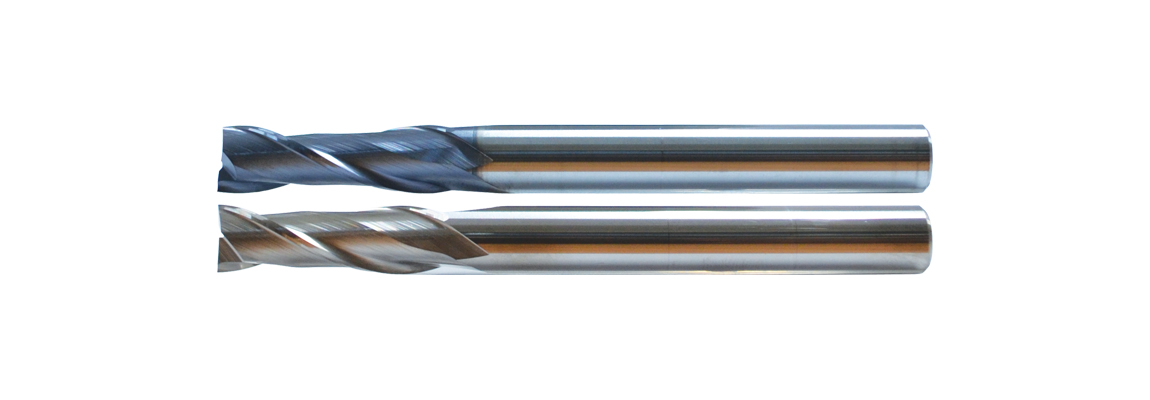

Solid Carbide 3 Flute End Mills – Regular Length – Plain Shank – Uncoated for Aluminium

Multi-purpose tool used for slotting and profiling.

02R

WORKS STD.

2-16

Solid Carbide 3 Flute Ball Nose End Mills – Regular Length – Plain Shank – Uncoated for Aluminium

For finishing of contours at high feed rates where a superior finish is required.

02S

WORKS STD.

3-16

Solid Carbide Single Flute End Mills – Regular Length – Plain Shank – Uncoated for Aluminium

For dry machining of soft materials.

02T

WORKS STD.

3-12

Solid Carbide 3 Flute Toroidal End Mills – Regular Length – Plain Shank – Uncoated for Aluminium

For minimum vibration in heavy profile machining.

02U

WORKS STD.

3-16

Solid Carbide 3 Flute Roughing End Mills – Regular Length – Knuckle Form – Coarse Pitch – Flatted Shank – Uncoated for Aluminium

Maximum stock removal at high feed rates in profiling applications.

03C

WORKS STD.

6-20

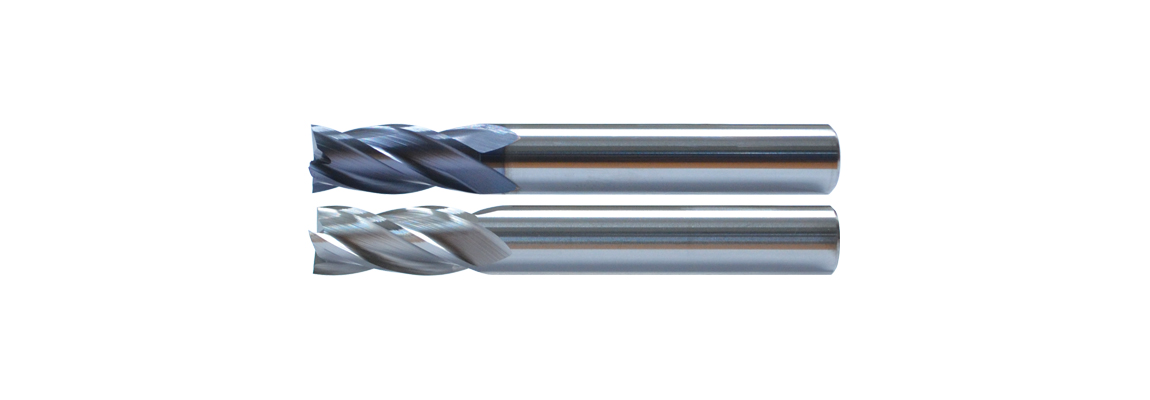

Solid Carbide 4 Flute Roughing End Mills – Regular Length – Knuckle Form – Fine Pitch – Flatted Shank – Coated

Maximum stock removal at high feed rates in profiling applications.

03E

WORKS STD.

6-20

Solid Carbide 4 Flute Roughing End Mills – Regular Length – Flat Crest – Fine Pitch – Flatted Shank – Coated

Maximum stock removal at high feed rates in profiling applications.

03F

WORKS STD.

6-20

Solid Carbide 6 Flute Finishing End Mills – Regular Length – Plain Shank – Coated

Designed for peripheral milling as a finishing operation.

03G

WORKS STD.

6-20

Solid Carbide 6 Flute Hi-Feed End Mills – Regular Length – Plain Shank – Coated

Designed for peripheral milling of contours and complex shapes in hard materials.

03H

WORKS STD.

6-20

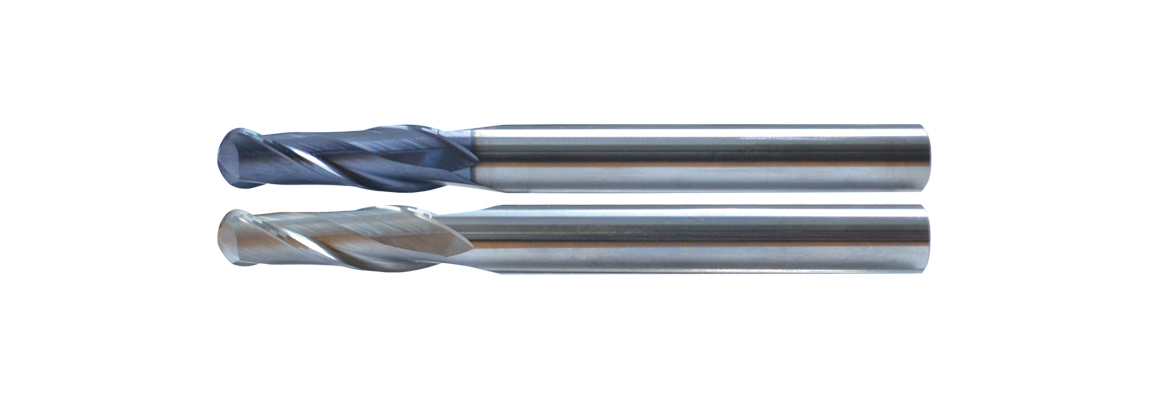

Solid Carbide 2 Flute Ball Nose Finishing End Mills – Long Series – Plain Shank – Coated

Designed for peripheral milling of contours and complex shapes in hard materials.

03J

WORKS STD.

4-20

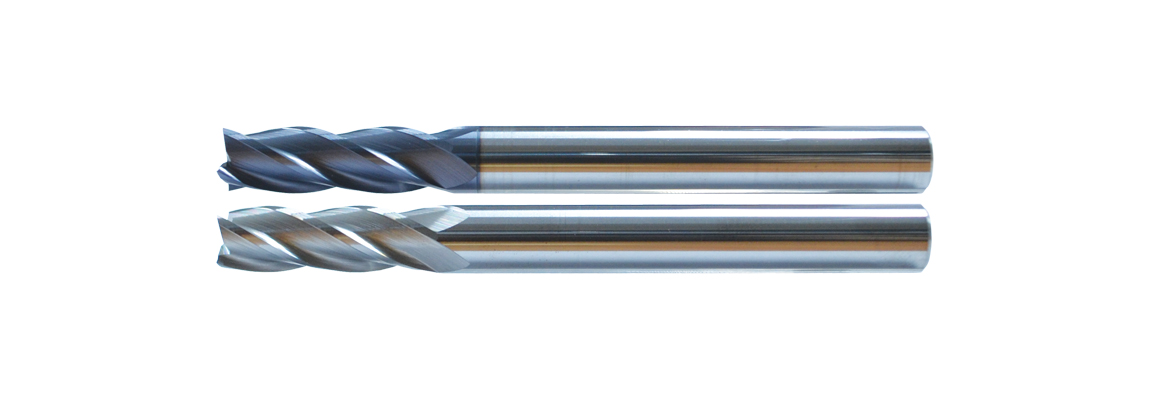

Solid Carbide 4 Flute VariCut End Mills – Stub – Flatted Shank – Coated

For roughing and finishing with high metal removal rates elliminating the use of multiple tools. Designed for tougher materials including Stainless steel and Titanium.

04V

DIN 6527K

5-20

Solid Carbide 4 Flute VariCut End Mills – Regular Length – Flatted and Plain Shank – Coated

For roughing and finishing with high metal removal rates elliminating the use of multiple tools. Designed for tougher materials including Stainless steel and Titanium.

03V

DIN 6527L

5-20

Solid Carbide 5 Flute VariCut End Mills – Regular Length – Flatted and Plain Shank – Coated

For roughing and finishing with high metal removal rates elliminating the use of multiple tools. Designed for tougher materials including Stainless steel and Titanium.

05V

DIN 6527L

5-20

Solid Carbide 2 Flute End Mills – Regular Length – Plain Shank – Coated and Uncoated

Milling keyways and slots to size in one cut. Designed for plunging operations.

03A

WORKS STD.

1-20

Solid Carbide 2 Flute End Mills – Long Series – Plain Shank – Coated and Uncoated

Milling keyways and slots to size in one cut. Designed for plunging operations.

03B

WORKS STD.

3-20

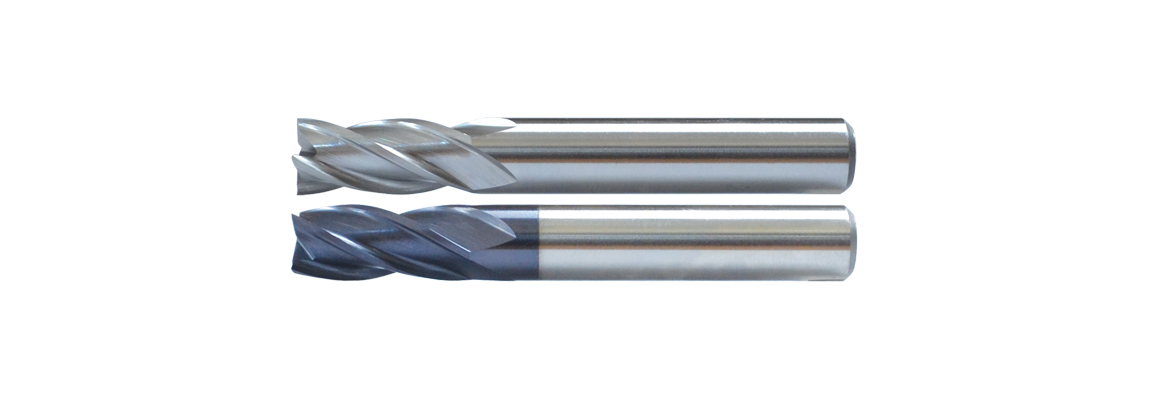

Solid Carbide 4 Flute End Mills – Regular Length – Plain Shank – Coated and Uncoated

For profile milling.

03K

WORKS STD.

1-20

Solid Carbide 4 Flute End Mills – Long Series – Plain Shank – Coated and Uncoated

For profile milling.

03L

WORKS STD.

3-20

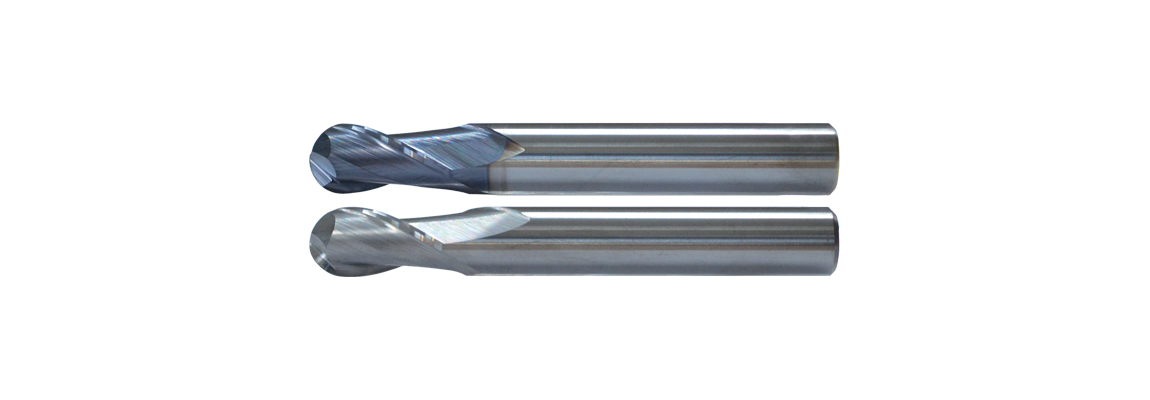

Solid Carbide 2 Flute Ball Nose End Mills – Regular Length – Plain Shank – Coated and Uncoated

Milling keyways and slots to size in one cut. Designed for plunging operations & contouring. Produces a radius at the bottom of the cut.

03M

WORKS STD.

1-20

Solid Carbide 2 Flute Ball Nose End Mills – Long Series – Plain Shank – Coated and Uncoated

Milling keyways and slots to size in one cut. Designed for plunging operations & contouring. Produces a radius at the bottom of the cut.

03N

WORKS STD.

3-20

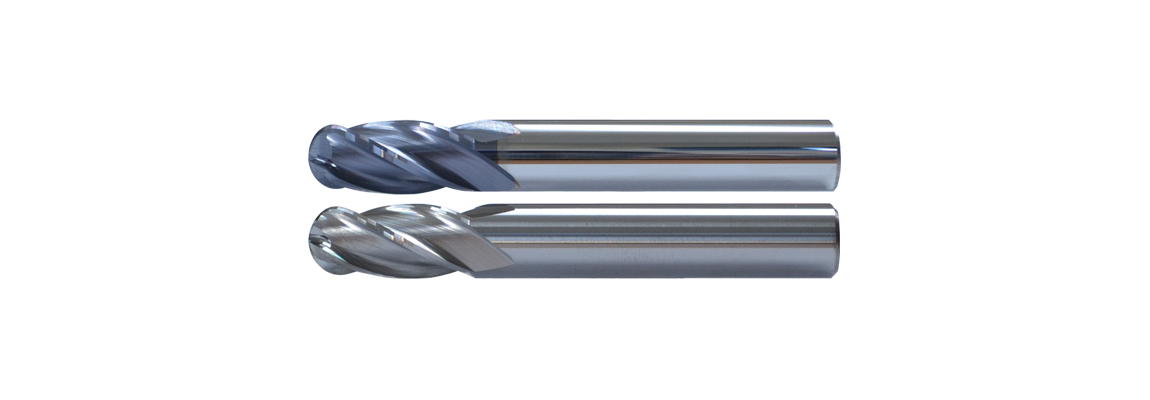

Solid Carbide 4 Flute Ball Nose End Mills – Regular Length – Plain Shank – Coated and Uncoated

For profile milling.

03P

WORKS STD.

1-20

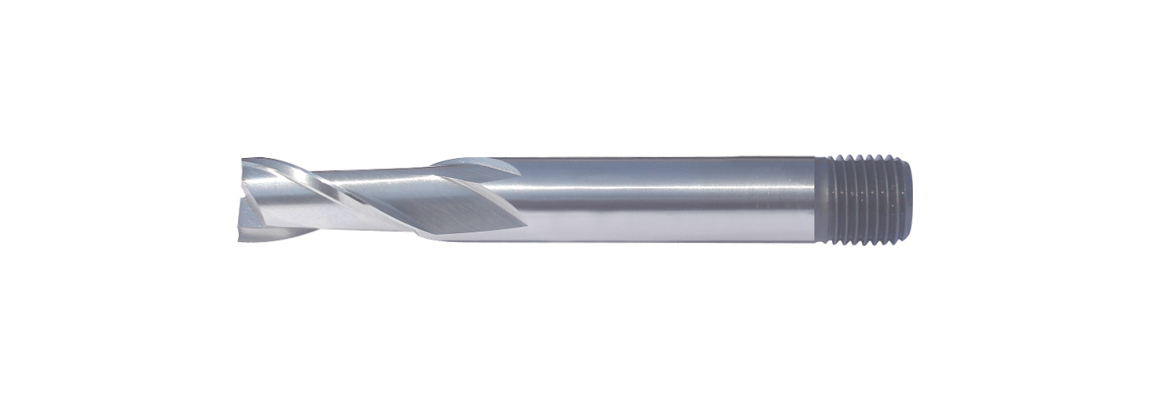

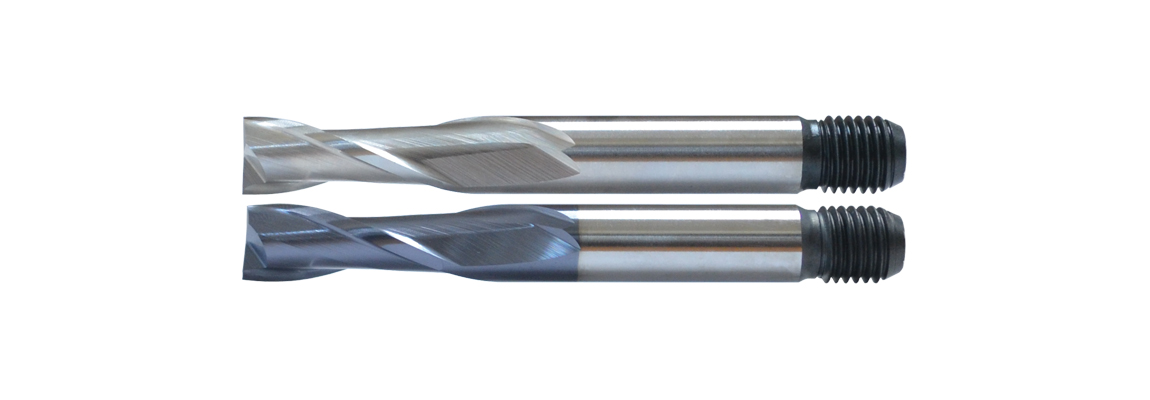

2 Flute End Mills (Slot Drills) – Regular Length – Threaded Shank – HSS

Milling keyways and slots to size. Designed for plunging operations.

321

323

DIN 327

BS 122

1.5-50

1/4-3/4

2 Flute End Mills (Slot Drills) – Long Series – Threaded Shank – HSS

Milling keyways and slots to size. Designed for plunging operations.

326

BS 122

2-20

2 Flute End Mills (Slot Drills) – Regular Length – Threaded Shank – HSS-Co8 – Uncoated and TiAIN Coated

Milling keyways and slots to size in one cut. Designed for plunging operations.

348

349

DIN 327

BS 122

1.5-50

1/16-2"

2 Flute End Mills (Slot Drills) – Long Series – Threaded Shank – HSS-Co8 – Uncoated and TiAIN Coated

Milling keyways and slots to size in one cut. Designed for plunging operations.

350

BS 122

2-20

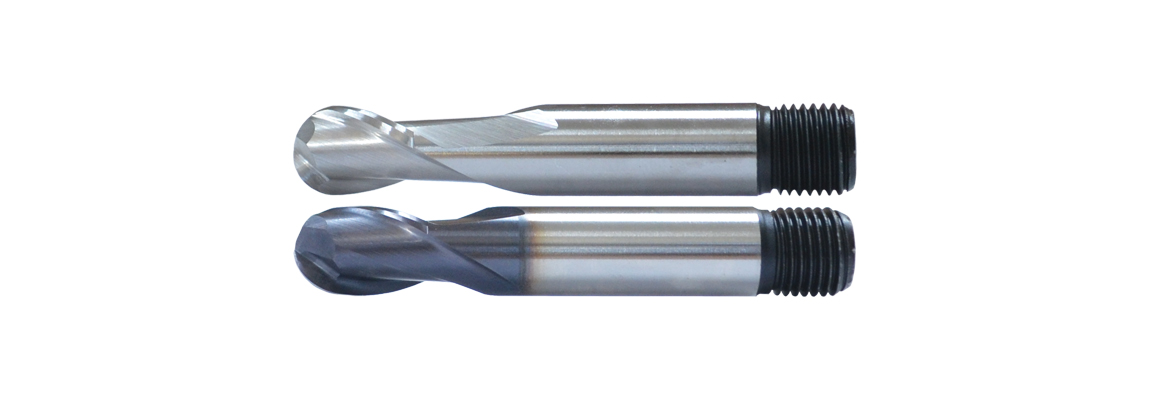

2 Flute Ball Nose End Mills – Regular Length – Threaded Shank – HSS-Co8 – Uncoated and TiAIN Coated

Milling keyways and slots to size in one cut. Designed for plunging operations & contouring. Produces a radius at the bottom of the cut.

340

DIN 327

2-25

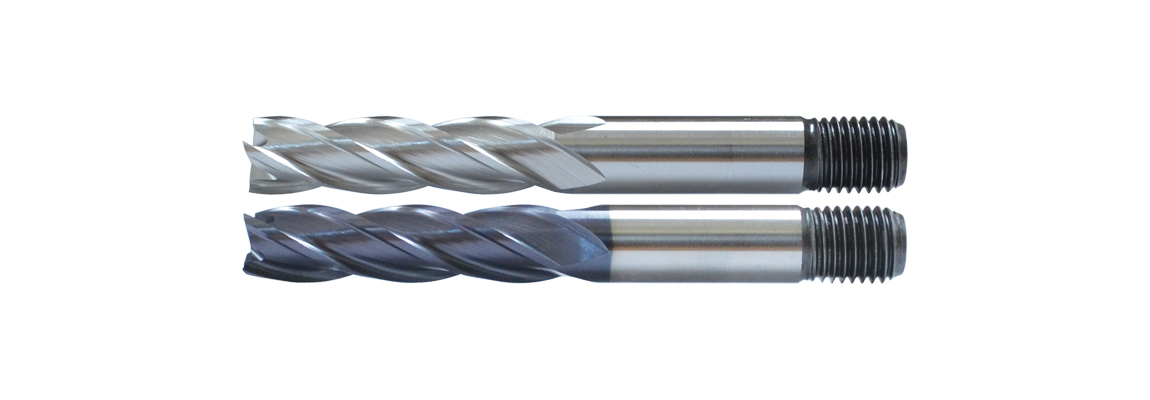

Multi-Flute End Mills – Regular Length – Threaded Shank – HSS

For profile milling.

301

303

BS 122

2.5-50

1/8-1"

Multi-Flute End Mills – Regular Length – Threaded Shank – HSS-Co8 – Uncoated and TiAIN Coated

For profile milling.

344

345

BS 122

2.5-50

1/8-3/4

Multi-Flute End Mills – Long Series – Threaded Shank – HSS-Co8 – Uncoated and TiAIN Coated

For profile milling.

346

BS 122

3-32

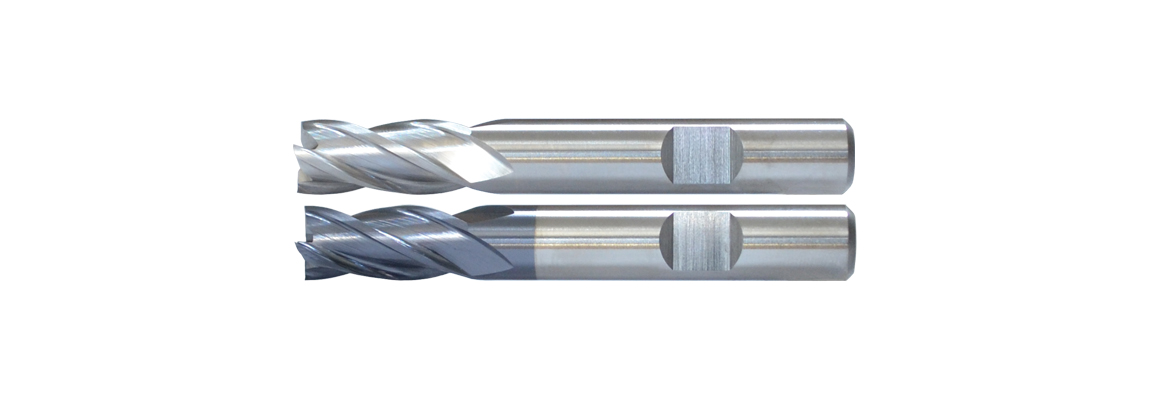

Multi-Flute End Mills – Regular Length – Flatted Shank – HSS-Co8 – Uncoated and TiAIN Coated

For profile milling.

359

DIN 844

3-25

Multi-Flute End Mills – Regular Length – Plain Shank – HSS-Co8 – Uncoated and TiAIN Coated

For profile milling.

314

DIN 844

3-25

Roughing End Mills – Regular Length – Threaded Shank – Knuckle Form – Coarse Pitch – HSS-Co8 – TiAIN Coated

Maximum stock removal at high feed rates in profiling applications.

316

BS 122

6-20

Roughing End Mills – Long Series – Threaded Shank – Knuckle Form – Coarse Pitch – HSS-Co8 – TiAIN Coated

Maximum stock removal at high feed rates in profiling applications.

318

BS 122

10-20

Corner Rounding Cutters – Threaded Shank – HSS-Co8

To produce a true radius up to a quarter of a circle application.

363

DIN 6518 FORM D

2-20

Corner Rounding Cutters – Flatted Shank – HSS-Co8

To produce a true radius up to a quarter of a circle application.

363

DIN 6518 FORM B

2-20

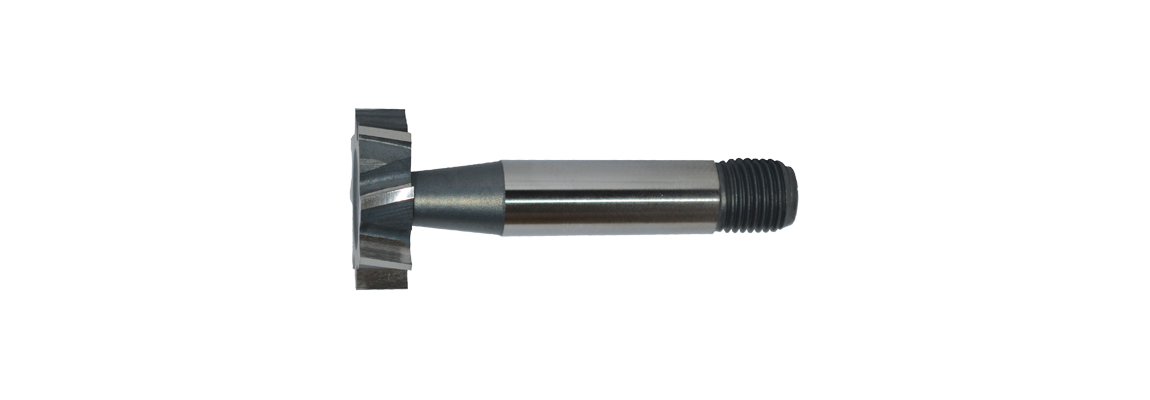

Woodruff Cutters – Threaded Shank – HSS-Co5

To produce a keyway to suit woodruff keys.

366

BASED ON DIN 850 TO SUIT DIN 6888 KEY

10.5-45.5

Woodruff Cutters – Flatted Shank – HSS-Co5

To produce a keyway to suit woodruff keys.

374

DIN 850

10.5-45.5

Woodruff Cutters – Threaded Shank – HSS-Co5

To produce a keyway to suit woodruff keys.

367

BASED ON

BS 122

204-1010

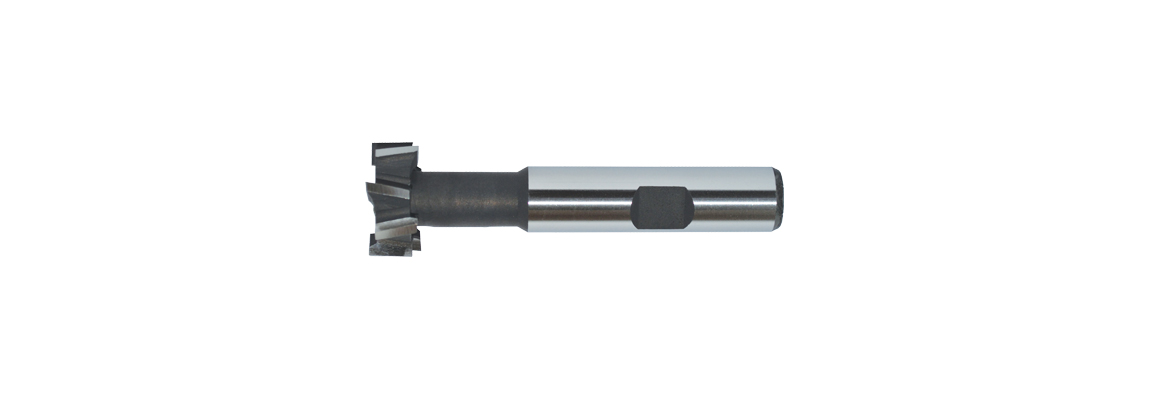

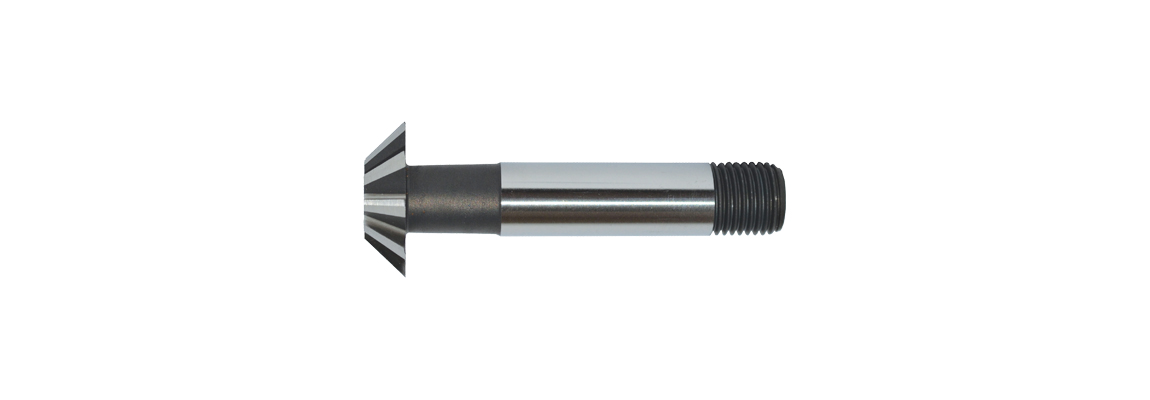

T-Slot Cutters – Threaded Shank – HSS-Co5

For opening out the bottom of previously milled slot to form a T-slot.

371

BASED ON

ISO 3337

DIN 851

6-16

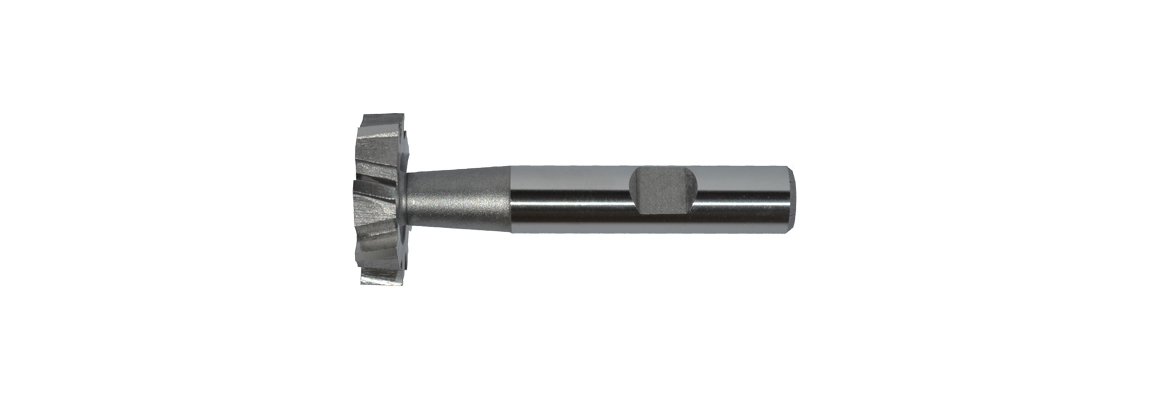

T-Slot Cutters – Flatted Shank – HSS-Co5

For opening out the bottom of previously milled slot to form a T-slot.

385

DIN 851

6-16

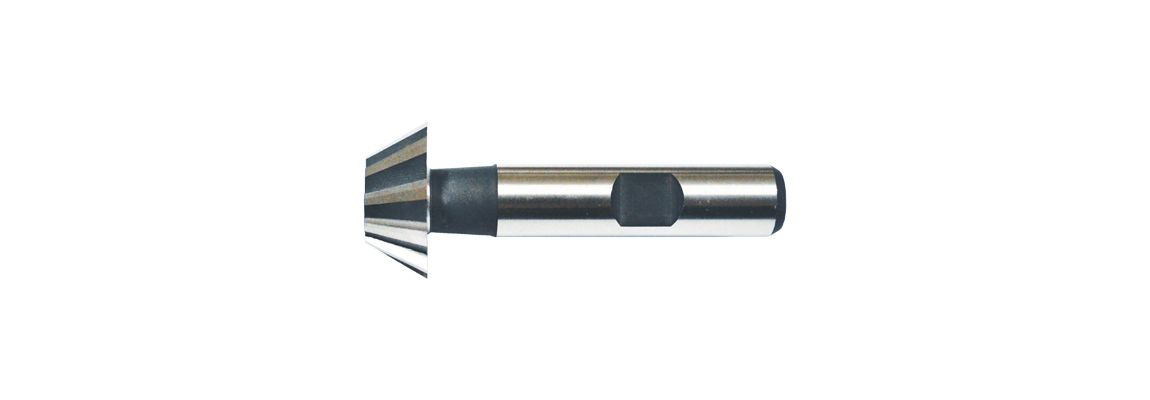

Dovetail Cutters – Threaded Shank – HSS-Co5

To produce dovetail slides for machine tool tables, jigs and fixtures.

376

BASED ON

DIN 1833

ISO 3859

16-40

Dovetail Cutters – Flatted Shank – HSS-Co5

To produce dovetail slides for machine tool tables, jigs and fixtures.

386

DIN 1833 FORM C

16-40

Inverted Dovetail Cutters – Threaded Shank – HSS-Co5

To produce opposite section of dovetail slide to Dovetail cutter.

378

BASED ON

DIN 1833

ISO 3859

16-32

Inverted Dovetail Cutters – Flatted Shank – HSS-Co5

To produce opposite section of dovetail slide to Dovetail cutter.

389

DIN 1833 FORM D

16-32

Slitting Saws – Fine Pitch – HSS

Narrow slotting and sawing applications in thin materials.

440-441

DIN 1837A

32-200